Page 1 of 1

Thunderbolt Rotator Question

Posted: Sat Feb 17, 2018 10:27 am

by Synther

How does the Thunderbolt rotator mechanism maintain an air-tight connection between the siren head and the blower pipe, while rotating? I couldn't imagine it using a gasket, because that would add more friction. I've been thinking about this for awhile, and I haven't been able to figure it out. Sensible answers only please! lol

Re: Thunderbolt Rotator Question

Posted: Sat Feb 17, 2018 10:29 am

by Tyler

Synther wrote: ↑Sat Feb 17, 2018 10:27 am

How does the Thunderbolt rotator mechanism maintain an air-tight connection between the siren head and the blower pipe, while rotating? I couldn't imagine it using a gasket, because that would add more friction. I've been thinking about this for awhile, and I haven't been able to figure it out. Sensible answers only please! lol

There are no air gaps. It's sealed shut basically.

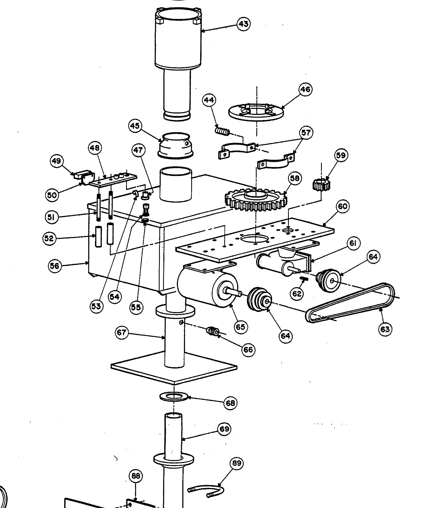

- Screen Shot 2018-02-17 at 4.32.25 AM.png (67.18 KiB) Viewed 2801 times

Re: Thunderbolt Rotator Question

Posted: Sat Feb 17, 2018 10:32 am

by Synther

If it were sealed, then how would it rotate with all the friction. I don't know why I cant wrap my head around this. Maybe because its 3:32 AM?

Re: Thunderbolt Rotator Question

Posted: Sat Feb 17, 2018 10:33 am

by Tyler

Synther wrote: ↑Sat Feb 17, 2018 10:32 am

If it were sealed, then how would it rotate with all the friction. I don't know why I cant wrap my head around this. Maybe because its 3:32 AM?

Look at my edited post above and think a little bit.

Re: Thunderbolt Rotator Question

Posted: Sat Feb 17, 2018 4:48 pm

by Brendan W

Basically it's because of tight fitment between parts and a bolt down clamp on the blower pipe that not only holds the rotator gear in place but also helps keep a seal between parts. It should also help too that there are gaskets underneath the chopper and between the flange and the mounting plate, which do aid in a seal.